Equipped with demister, our steam boilers reach the highest steam quality and purity available on the market

Steam boilers

Thanks to the presence of an electrically insulated neutral point, Elpanneteknik’s electrode boilers can connect directly to the common electrical grid without using a dedicated grounded transformer. The neutral point (the inner vessel) has a high resistance to earth, minimizing earth-fault currents to approximately 5 amperes in the case of a short circuit between phase and neutral.

Blowdown

Automatic surface blowdown maintains the appropriate conductivity in the boiler water. The expected efficiency loss, with ammonia and trisodium phosphate dosing, is less than 0.1%, with a demineralized makeup water conductivity of less than 1,0 μS/cm.

Feedwater supply

Demineralized and deaerated water is pumped from the feedwater tank into the outer vessel to maintain constant overall water volume.

Power and steam output

Power and steam output is determined by the water level in the inner vessel in contact with the electrodes and the conductivity of the water. Power can be regulated from 0% to 100%.

Water circulation

The circulation pump transfers the water from the outer vessel to the inner vessel. For redundancy, two pumps can be installed. If the pump in operation fails, the other pump starts automatically. Water level in the electrically insulated inner vessel is regulated by the amount of water pumped in and the inner vessel control valve that allows water to drain out into the outer vessel.

Automatic surface blowdown maintains the appropriate conductivity in the boiler water. The expected efficiency loss, with ammonia and trisodium phosphate dosing, is less than 0.1%, with a demineralized makeup water conductivity of less than 1,0 μS/cm.

All electrode boilers are high in efficiency due to the principle of using water as a resistor. So whether it’s immersion or jet type boilers, overall efficiency (including blowdown and insulation losses) is approximately 99%. High voltage electrical boilers are always electrode boilers. Elpanneteknik Sweden AB has the market’s widest product line, ranging from 1 MW to 80MW, from 6Kv to 20kV. Elpanneteknik immersion boilers are simple in concept and operation and don’t have the complicated nozzle arrangements found in jet/spray-type designed boilers, which wear out and require frequent adjustments for optimal functionality. Equipped with a demister, Elpanneteknik Boilers offer the highest levels of efficiency on the market.

High voltage

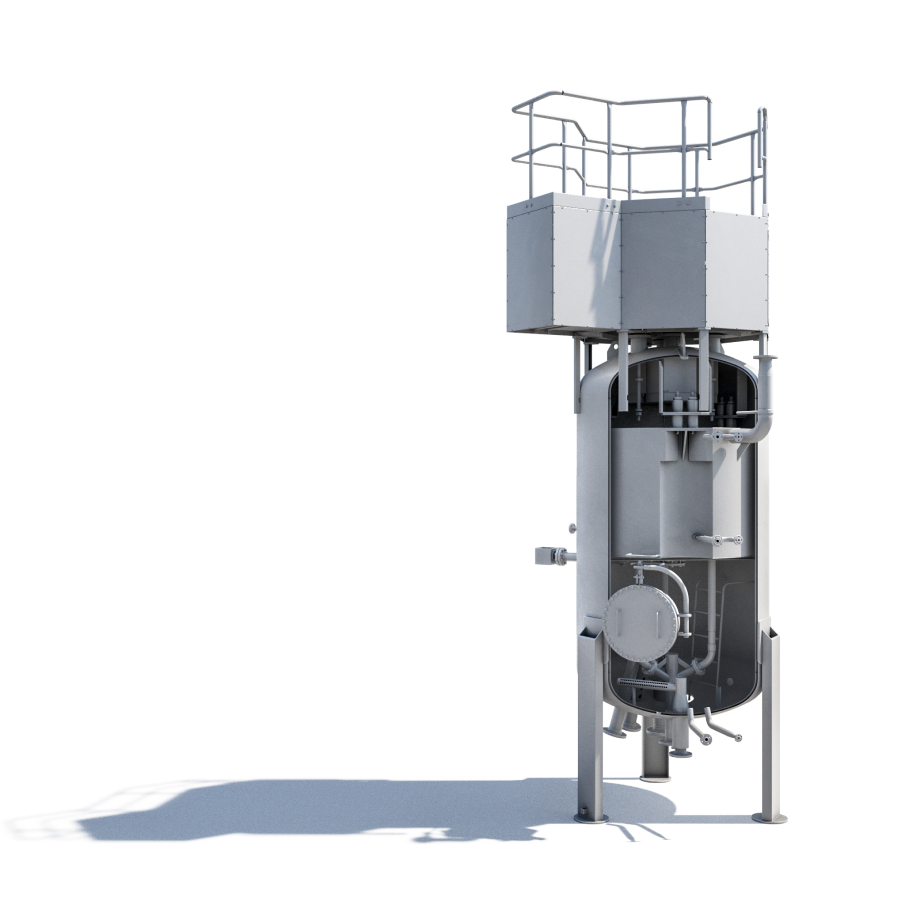

IMMERSION TYPE HIGH VOLTAGE BOILER DESIGN AND PRINCIPLES OF OPERATION

Boilers are comprised of an outer and an inner vessel. The inner vessel also forms the electrical system’s zero point.

The three phase electrodes are located in the inner vessel. Water makes up for the electrode boilers heat generating resistance. The amount of electrical energy converted into heat, the boiler capacity output, relies on the conductivity of the water and the electrode surface, which is regulated by the water level covering the electrodes. The boilers are guaranteed never to run dry, as electrical power is automatically cut if water level to low.

The high-quality electrode designed by Elpanneteknik Sweden is comprised of a number of electrodes mounted on an electrode plate. Each electrode is suspended in insulator bushes at the boiler top. The amount of current passing through the water depends on the conductivity of the water and the electrode surface as regulated by the water level.

At the bottom of the inner vessel, a control valve with external actuator is installed. A circulation pump is connected to the suction pipe of the outer vessel. Pressure lines are connected to the inner vessel beneath each phase electrode. The pump is speed controlled, varying the flow with the capacity load of the boiler.

In almost all cases, our boilers can be connected directly to the common electrical grid without using a dedicated grounded transformer.

Elpanneteknik’s boilers utilize a blowdown recovery device to minimize energy loss due to blowdown. Overall efficiency, even when including blowdown losses, is more than 99.9%. Immersion electrode boilers can operate from 0% to 100% power level with the same efficiency, close to 100%.

The boilers can be equipped for supplying superheated steam.

Low voltage

In low voltage electrical steam and hot water boilers, an electronic step controller programmed to fit the boiler size regulates power and boiler temperature. Electrodes are replaced by electrical elements.

All Elpanneteknik boilers are supplied with an option to connect an external signal for temperature set-point and step limitation. Furthermore, a PLC with touch-screen makes it easy to use for non-technical staff.

Key safety functions can be operated separately from the PLC to ensure redundancy. Elpanneteknik Sweden AB have long and well-proven experience delivering containerized solutions.

Technical Information

For more information about this product range, please see the technical data sheet.